NON-FERROUS METALS INDUSTRY

APPLICATION OF REFRACTORY MATERIALS

DGC Refractories offers a specialised range of high-performance shaped refractories designed to withstand the extreme thermal, chemical, and mechanical demands of non-ferrous metal processing. With over a century of industrial heritage, we support operations in copper, aluminium, nickel, zinc, and lead production with durable materials that enhance furnace performance, extend campaign life, and ensure energy efficiency.

From anode furnaces to rotary kilns, our materials are engineered for precision and endurance.

KEY APPLICATIONS

Our shaped refractory solutions are optimised for:

-

Flash Smelting Furnaces

-

Anode Furnaces

-

Rotary Furnaces

-

Electric Holding & Melting Furnaces

-

Slag Cleaning Furnaces

-

Tapping Channels & Launders

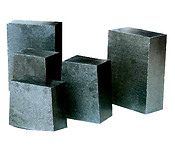

SHAPED REFRACTORIES

DGC Refractories supplies industry-proven brick systems for harsh metallurgical environments, offering exceptional corrosion resistance, thermal shock stability, and structural integrity.

MAGNESIA CHROME BRICKS

-

Magnesia Bricks – For high-load, high-temperature environments

-

Magnesia-Carbon Bricks – Ideal for ladle linings and induction furnace walls

-

High Alumina Bricks – Strong and thermally stable for general furnace linings

-

Silicon-Carbon Bricks – Enhanced thermal shock resistance and erosion control

MAGNESIA & ALUMINA SYSTEMS

-

Fused-Rebonded Magnesia Chrome Bricks - Excellent slag resistance, suitable for flash smelters and converters

-

Fused Semi-Rebonded Magnesia Chrome Bricks - High performance under fluctuating thermal load

-

Direct-Bonded Magnesia Chrome Bricks - Long service life in high-corrosion zones (e.g., sidewalls, tuyeres)

FUSED & REBONDED

DESIGNED FOR

DEMANDING CONDITIONS

OPERATIONAL CHALLENGE

-

Intense slag corrosion in flash smelters

-

High thermal cycling near tuyeres or tap zones

-

Mechanical wear in high-impact zones

-

Elevated heat retention with process stability

DGC REFRACTORIES SOLUTION

-

Fused rebonded magnesia chrome bricks with superior chemical durability

-

Semi-rebonded chrome-magnesia for thermal shock stability

-

High alumina and SiC-carbon bricks for erosion and spalling resistance

-

Magnesia-carbon and direct-bonded bricks for temperature control

MATERIALS

FOR INDUSTRIAL

METALS APPLICATIONS

Our refractory materials are tailored to the needs of both ferrous and non-ferrous operations, including:

-

Copper – anode furnaces, flash smelting, converters

-

Aluminium – holding furnaces, launder channels

-

Zinc & Lead – rotary furnaces, slag zones

-

Nickel – smelting reactors and electric furnaces

All materials are manufactured under stringent QA/QC protocols, with third-party inspection (SGS, CTC, CST, Bureau Veritas) available on request.

INDUSTRIAL

COMMITMENT

At DGC Refractories, we bring together:

-

Over 100 years of industrial service history

-

Specialised materials tailored for non-ferrous metallurgy

-

Regionally responsive supply and technical support

-

High-volume production capacity and robust quality management

We deliver performance where others promise it.