GLASS INDUSTRY

APPLICATION OF REFRACTORY MATERIALS

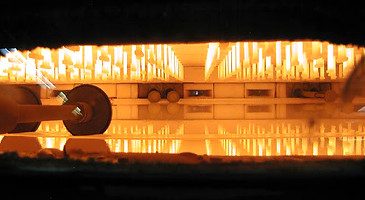

DGC Refractories supplies a specialised range of shaped refractory materials for the glass manufacturing industry. Our solutions are engineered to meet the extreme thermal, chemical, and mechanical demands of glass furnaces, ensuring long service life, minimal downtime, and consistent product quality.

Whether for container glass, float glass, or fiberglass production, our high-performance materials are tailored to each application zone to ensure reliability and efficiency.

KEY APPLICATIONS

We provide refractory solutions for:

-

Container Glass Tanks – Suitable for flint and coloured glass lines

-

Float Glass Furnaces & Tin Bath Bottoms – With high integrity for smooth float processes

-

Fiberglass Furnaces – Offering erosion resistance and high thermal shock stability

-

Regenerators, Refiner Zones & Superstructures – Engineered bricks for thermal uniformity

SHAPED REFRACTORIES

Our refractory materials are designed to withstand the thermal gradients and corrosive environments found throughout glass melting and forming operations:

-

Fused Cast AZS Bricks – Excellent corrosion resistance and high thermal stability

-

Silica Bricks – High refractoriness under load and excellent creep resistance

-

Zircon Bricks – Superior glass corrosion resistance in critical zones

-

Sillimanite Bricks – Low thermal expansion and strong structural integrity

-

Mullite Bricks – High strength and thermal shock resistance

-

Corundum Bricks – For extreme wear and chemical exposure

-

Corundum-Mullite Bricks – Balanced strength, insulation, and alkali resistance

-

Low Porosity Fireclay Bricks – Ideal for checker packs and insulation layers

-

Magnesia Bricks – Suitable for regenerator and batch charging areas

Every material is tested to meet exacting standards for density, porosity, thermal conductivity, and corrosion resistance.

ENGINEERED

FOR GLASS QUALITY

& FURNACE LONGEVITY

OPERATIONAL CHALLENGE

-

Alkali and glass corrosion

-

Sudden thermal shock

-

Furnace roof deformation

-

Wear in throat and superstructure zones

DGC REFRACTORIES SOLUTION

-

Zircon and AZS bricks for furnace contact zones

-

Mullite and sillimanite bricks with high TSR

-

Silica bricks with high creep resistance and dimensional stability

-

Corundum-mullite bricks for high erosion resistance

All DGC refractory products for the glass industry are manufactured under strict QA protocols, with third-party validation (SGS, CTC, CST, or Bureau Veritas) available on request.