FOUNDRY INDUSTRY

APPLICATION OF REFRACTORY MATERIALS

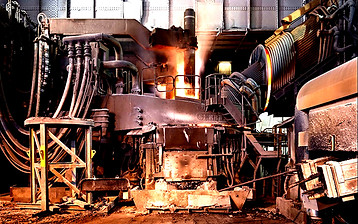

DGC Refractories delivers tailored monolithic refractory solutions for foundry operations, supporting a wide range of metal casting environments. From iron and steel to aluminium and copper, our solutions are engineered to perform under intense thermal and mechanical conditions while ensuring efficiency, reliability, and reduced downtime.

FOUNDRY APPLICATIONS

-

Induction Furnaces

-

Holding & Casting Ladles

Our products are used across:

-

Electric Arc Furnaces (EAFs)

-

Tundishes and Pouring Basins

-

Crucibles & Channel Furnaces

MONOLITHIC

REFRACTORIES

& THERMAL SOLUTIONS

We offer an integrated portfolio of materials, all rigorously tested to meet the specific demands of both ferrous and non-ferrous casting environments.

MONOLITHIC REFRACTORIES

-

Full range of castables (standard, low-cement, ultra-low cement)

-

Ramming masses and gunning materials for flexible installation

-

Dry vibratable materials for induction furnace linings

-

Abrasion-resistant linings for high-wear zones

AUXILIARY PRODUCTS

-

Capping & Sprout Materials – for pouring channels and impact pads

-

Mica-Based Slip Plane Materials – enhances furnace lining longevity

-

Non-Wetting Zircon Washcoats & Pitching Compounds – for aluminium and copper

-

Coil Mudding Cements – for secure coil protection in induction systems

-

Insulation Bricks & Pile Bricks – thermal buffering for outer linings

CERAMIC FIBER PRODUCTS

-

Blankets, boards, paper, and vacuum-formed modules

-

High-temperature insulation for furnace linings and roofs

PERFORMANCE YOU

CAN COUNT ON

OPERATIONAL CHALLENGE

DGC REFRCATORIES SOLUTION

-

High thermal cycling

-

Aluminium non-wetting issues

-

Erosion in high-flow areas

-

Coil damage in induction systems

-

Low-cement and ultra-low cement castables

-

Zircon-based washcoats and non-wetting linings

-

Steel-fiber reinforced castables and abrasion-resistant mixes

-

Specialized coil mudding cements and mica-based insulation

All materials can be independently certified via third-party labs such as SGS, CTC, or Bureau Veritas, upon request.

BUILDING EFFICIENCY INTO EVERY CAST

At DGC Refractories, our goal is to empower foundries with dependable solutions that enhance furnace performance, reduce maintenance cycles, and extend campaign life. Backed by decades of technical expertise and a commitment to quality, we are your trusted partner in achieving casting excellence.

For a stronger lining. A smoother pour. A better result.