SILO WHIP OR CARDOX BLASTS

- DGC AFRICA

- Oct 21, 2021

- 2 min read

The silo whip and Cardox blasting are two revolutionary silo cleaning techniques that both significantly improve the safety profile of silo cleaning operations by eliminating the need for human entry into the silos at any point during the cleaning process.

Both methods have also been found to increase the efficiency of silo cleaning operations as works are completed within much shorter timeframes compared to the traditional manual methods of cleaning. How then does one choose a technique to employ for a given task?

We recently asked this question to one of our engineers who is involved in several silo cleaning projects annually, below is his response: Working on various sizes and types of silos has come to show the diversity in the use of the Silo Whip and Cardox blasting systems. Both systems are effective in their own ways.

Generally speaking:

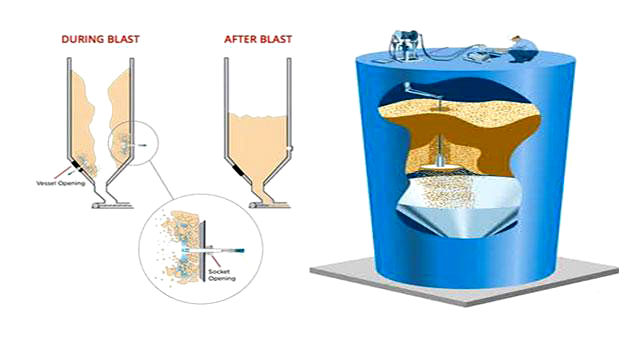

Cardox blasting works very well for clearing blockages at the bottom of a silo, thereby solving problems linked to restricted product flow.

The silo whip works very well where material buildup is on the side walls of a silo, thereby solving problems linked to reduced silo capacity.

However, while working with one of our long term clients we previously experienced an unusual material build up inside the vessel/bin. The blockage was roughly 3 meters from the bottom of the vessel and blasting proved to be highly ineffective as the angle of the buildup was out of its blasting reach. The bin also had a small width leaving little room to maneuver the arm of the silo whip. Despite the constraints, the ultimate solution involved strategically positioning and lowering the silo whip’s rotating head next to the material and cut it loose. It was the first time such a blockage occurred at the specific site and was quite the problem.

In conclusion; the two systems work very well hand in hand, whenever one of them is constrained, the other normally finishes the job.

Comments